Electro-Chemical Etching

Electro-Chemical Etching is a marking method that etches a perfectly high contrast, permanent mark into any material that conducts electricity. It does not heat up the material and does not weaken or alter the microstructure of the material. The Method as well as the machinery are not harmful to personnel or the environment.

Electro-Chemical Etching is a process that is extremely fast and considerably cheaper than other marking methods. It is known for bringing out great details accompanied by a fast batch setup. These characteristics make it a common marking method for medical instruments, aircraft parts, tools, cutlery and so on.

Machines for electro-chemical etching

TUS is an OEM for a complete line of electro-chemical etching machines. The machines range from manual machines for occasional use to automated machines for a high volume environment.

All machines are sold as ‘plug and play’ solutions and require no setup. We will be happy to work with you on special designs and applications.

We publish prices and availability of our basic machines in our online store.

Stencils for electro-chemical etching

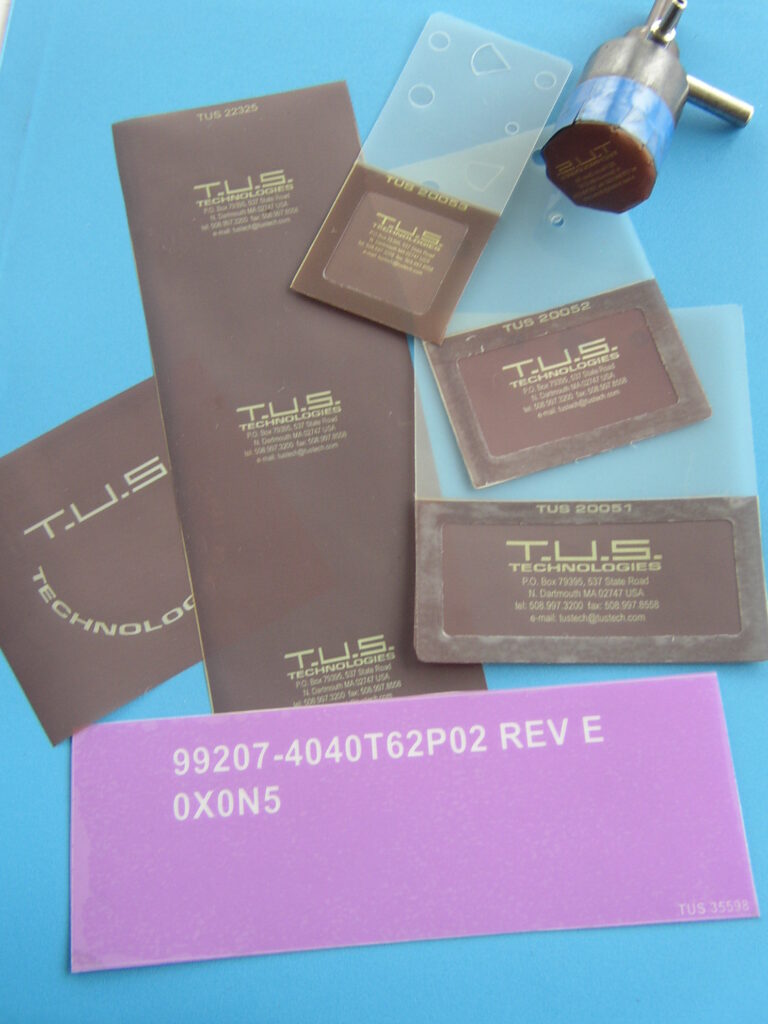

TUS produces high performance etching stencils as well as material for the production of stencils at your site (self stencil solutions).

The high performance stencils are made to your specifications. The information on the stencil can be text, logos, information from technical drawings or any kind of digital file. We have extensive graphical capacities on hand and so far we have mastered all challenges. We offer a proof in pdf form that we send you in pdf form.

All stencil orders that reach us until 10:30am are shipped the same day.

The easiest way to start a stencil order is our contact page.

Please also check our dedicated page about the different options for stencils.

stencils for electro-chemical etching (cont.)

Our high performance stencils hold up for a long time – our marking job shop marks a minimum of 5,000 etches per image, but we have seen more than 10,000 etches per stencil image.

The high performance stencils come in two versions: the gold stencil material is a see-through material and makes alignment and positioning easy. Our brown material is very sturdy and is the go-to solution for deep etches.

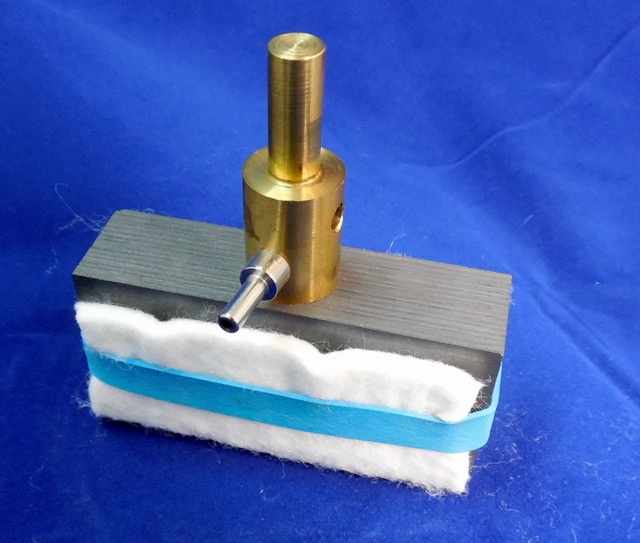

Stencils come in two different formats: sheet stencils and framed stencils. Framed stencils are typically used in automated machines to keep the stencil in place. Our stencil frames fit the stencil holders of all known machines for electro-chemical etching.

Please also check our dedicated page about the different options for stencils.

Etching electrolytes and Self stencil material

TUS manufactures and sells all necessary supplies for the etch marking process.

Electrolytes determine the appearance of the mark. They are specific to the alloy and the appearance of the mark (Surface etch vs. deep etch). TUS offers a full range of electrolytes that cover all known metals. We share all this detail knowledge with you in a file that is available on our Info and Download page.

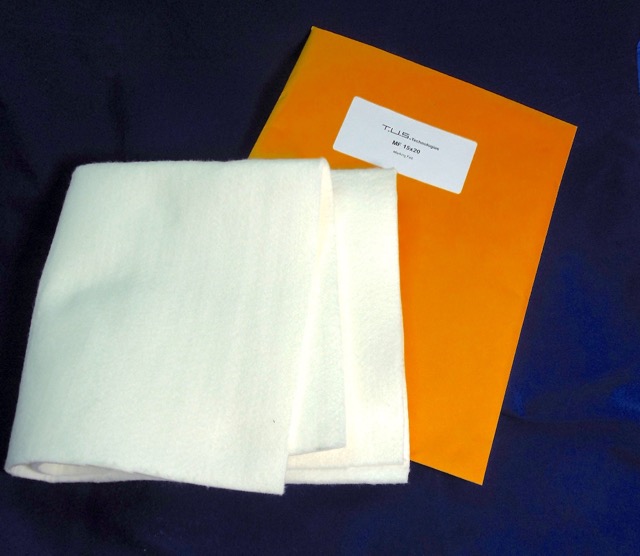

We also offer a variety of options for the production of stencils at your site like photo-exposing materials, thermo-stencil material and other options.

Pricing for supplies and more detailed info can be found in our online shop.

Other supplies and spare parts

Often overlooked in their importance for the mark quality are supplies for electro-chemical etching: Marking Felt, cleaner/Neutralizer, stencil cleaner, etc.. We produce a full range of all necessary supplies backed by our extensive experience from our in-house marking operation.

Most spare parts for our machines are stock items. Call us and we will send out a spare part the same day.

TUS will manufacture custom fixtures for your specific needs based on your part drawings.

Pricing and more detailed info can be found in our online shop.

F.A.Q.

Frequently asked questions about electro-chemical etching

The easiest way is to send us a message on our contact page. You will receive an answer that details prices, the process and what we will need from you.

For surface etches, typically with a 12 Volt AC current you should get 5,000+ etches from each image of your stencil. For a deep etch, typically done with 24 Volt DC you should be able to get out 40-50 etches per image. The trick with deep etches is to not keep the handstamp in place during etching rather than wiping across the opening of the stencil multiple times to keep it cool. This extends the life of the stencil and improves your mark quality.

We offer an in depth description of the etching process on our download page. The short version:

Electrochemical Etching is non-destructive, fast, clean, and non-harmful to the user. Permanent inscriptions are made in seconds. Mild electrolyte and low voltage current etch the metal surface through openings in a stencil. Only the legend in the stencil is etched into the part surface. Marks/inscriptions can cover very small to large areas including curved surfaces. Depth, darkness and shade of the inscription are controlled through time, current, electrolyte and marking cycle.

The answer to this question depends on the alloy you are etching. We offer a comprehensive list of solutions in our download section. As a general starting point use 12 Volt AC for surface etches and 24 Volt DC for deep etches.

Spider webs or erratic lines are a sign that there are cracks in the stencil. Cracks in stencils are typically induced by bending, kinking of the stencil material or improper storage. Taping the stencil on multiple edges and then removing it like a band-aid is a perfect way to induce cracks – tape down on one end only.

Electro-chemical etching is safe. The current has low voltages and typically low currents. The electrolytes are mild salt solutions. The used chemicals are safe although they should not be taken internally. They can be stored in any adequate storage place and have an unlimited shelf life. Pressure of all pneumatic mechanisms in our machines have been setup in a way that they can not do harm to the operator.

Acid Etching is a marking method that involves a highly acidic paint. Please check our paint marking section

These processes are used to create fine detail metal parts from sheet metals. It has nothing to do with our processes, but we will be happy to connect you with a very competent partner we work with. Just send us a short notice.